Every second counts in any high-volume packaging operation. Whether it’s an e-commerce fulfilment centre, a manufacturing facility, or a distribution warehouse, the speed and consistency of your packaging line directly impact your bottom line. Yet many Australian businesses still rely on manual box sealing methods that create unnecessary bottlenecks, introduce variability, and quietly drain productivity from their operations.

Manual taping is often the unnoticed reason for lessened throughput and higher labour costs. When operators seal hundreds or thousands of cartons daily, the cumulative time it takes to cut the tape, line up boxes, and ensure appropriate sealing goes up surprisingly fast. More importantly, though, is that manual processes are inconsistent by nature. Some boxes are sealed with too much tape, others with not enough. The fatigue of your staff leads to mistakes, and improperly sealed cartons result in damaged goods and expensive returns.

This is where the automatic carton taping machines come into play to change how businesses approach their packaging operations.

The Real Cost of Manual Box Sealing

Before considering an automation solution, it’s worth understanding the true cost of manual sealing. Apart from obvious labour costs, manual taping creates a number of hidden inefficiencies. Workers who spend their days taping boxes can be better utilised in other value-added processes like quality control, inventory management, or processing orders. Variability in manual sealing means inconsistent presentation, and this can affect the way your brand is perceived once products are delivered to customers.

Then there is human error. A hurried taping job may result in flaps being partially unsealed. Too much tape is wasted, adding to the costs. And when you are sealing variable-sized boxes all day, manual adjustments slow down the entire line- a bottleneck that affects operations upstream and downstream.

How Automatic Carton Taping Machines Work

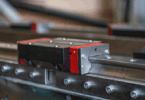

Automatic carton sealing machines meet such challenges head-on through intelligent design and robust engineering. Built with rugged steel construction, it’s designed for round-the-clock operation in demanding environments.

Advanced sensors automatically detect the dimensions of cartons and adjust the width, applying tape to both the top and bottom of boxes simultaneously. This dual-sealing feature effectively doubles your sealing speed compared to single-sided operations. The machine includes safety guards on both sides and an infeed conveyor for parcel alignment. It is ideal for fast, high-volume production lines where speed and consistency really matter.

These machines have the capability to automatically adjust to random box sizes without requiring the intervention of an operator. A typical warehouse or fulfilment centre could be packing everything from small electronics to large appliances, all of which would require different box sizes. Some products have automatic detection that enables the machine to automatically readjust in real time and constantly produce consistent sealing quality regardless of the carton dimensions.

Reducing Downtime through Smart Engineering

Downtime is the enemy of productivity in any packaging operation. These machines are specifically engineered to minimise unplanned stoppages thanks to a number of design features. For example, their rugged steel construction ensures durability that withstands the rigours of continuous operation. They aren’t lightweight machines that need to be continually repaired or adjusted. They’re built to handle high-volume environments day in and day out.

Practical design decisions further reduce maintenance-related downtime. Changing tape rolls is quick and easy with the cassette head system. Rather than threading tape through convoluted mechanisms, an operator can swap out cassettes in moments and get the line back up and running without extended interruptions.

They also support different types of tapes for flexibility in your operations. From the traditional packaging tape to the more eco-friendly, water-based paper tapes, This means you are not stuck to consumables but can decide according to cost, performance, and environmental concerns.

The Business Impact: Real Numbers That Matter

The benefits of automatic carton sealing span many dimensions of operation. Labour cost reduction is often the most immediate and visible impact. When you free staff from repetitive taping tasks, you can reduce either your headcount or redeploy those workers to roles that generate more value for your business. A warehouse that might need three people to handle manual sealing may be able to function quite efficiently with just one person to monitor the automated system.

Automation drastically reduces error rates. Consistent tape application means fewer improperly sealed boxes, reducing the risk of damaged goods in transit. This, in turn, leads to lower return rates, fewer customer complaints, and a better brand reputation. Quality becomes predictable rather than variable when each box that leaves your facility is sealed to the same high standard.

Another often-overlooked benefit is tape waste reduction: Automatic machines apply precisely the amount of tape needed for secure sealing, nothing more. This precision adds up over time into significant savings on consumables. Some operations are reporting tape usage reductions of 20 to 30 percent after switching from manual to automatic sealing.

Sustainability and Environmental Considerations

These machines offer compatibility with sustainable packaging materials for businesses committed to reducing their environmental footprint. The equipment works seamlessly with fully recyclable water-based paper tapes that will enable you to move away from plastic-based alternatives without any sacrifice of your sealing performance. This compatibility helps align your packaging operations with broader corporate sustainability goals while maintaining the speed and reliability you need.

The reduced tape waste mentioned earlier also leads to several environmental benefits. Less tape consumed means less material waste, lower shipping weights for your consumables, and a reduced overall environmental impact from your packaging operations.

Local Support Makes the Difference

Investing in packaging automation is a significant decision, and the quality of support you get is just as important as the quality of the machine itself.

In addition there is warranty coverage, some products also maintain a complement of factory-trained field service technicians throughout Australia. That means when you need assistance, you’re dealing with local professionals who know your equipment and can reach you fast. Spare parts are readily available from Australian warehouses, minimising downtime if the need for maintenance or repairs arises.

Through regular health checks, potential issues are caught before they create downtime, and detailed reports of machine condition and adjustments made during the visit are included.

Integration and Scalability

Contemporary packaging operations rarely use stand-alone equipment. Automatic carton taping machines function well within integrated packaging lines, most especially with carton erectors. When this is married to automatic box building, you get a seamless end-to-end process that involves little human intervention.

This integration capability becomes especially valuable as your business grows. Start with a single automatic taping machine in your busiest line, and add more units or integrate with additional equipment as volumes increase. Because these systems are modular, you’ll be able to scale your automation investments in step with business growth, rather than making massive capital expenditures all at once.

Making the Investment Decision

For operations managers and decision-makers who evaluate packaging automation, a number of variables should frame your assessment. Current volumes matter: if you’re sealing hundreds of cartons daily, the return on investment timeline becomes quite attractive. Labour costs in your market are another important variable. In regions where finding and retaining warehouse staff is difficult, automation provides operational consistency independent of labour market fluctuations.

Also relevant are the types of different box sizes you handle. The feature of automatic detection and adjustment on specific machines benefits operations with an extremely high number of different carton dimensions the most. If you have current issues relating to quality or high rates of return due to package failure, the consistency of automated sealing can address these problems while improving customer satisfaction.

Also consider your growth trajectory: If you’re anticipating increasing volumes, then automating now positions you to handle such growth without proportional increases in labour costs or space requirements.

Getting Started with Automation

For businesses ready to move forward, specific packaging experts will conduct an on-site assessment of your current packaging line, analyse your processes for bottlenecks, and give estimates on potential gains from automation. Such a consultation approach ensures you select the equipment that matches your needs rather than adopting a one-size-fits-all solution.

The assessment generally involves a look at your current throughput, labour allocation, box size variations, and space constraints.

Way Forward

In today’s competitive business environment, operational efficiency is not optional. Every process that can be optimised contributes to your ability to compete on price, speed, and quality. Manual box sealing represents exactly the kind of repetitive, variable, and time-consuming task that automation handles brilliantly.

Automatic carton taping machines offer a proven solution backed by decades of engineering expertise and supported by local Australian service teams. Whether the aim is to save labor costs, improve throughput, attain more consistency, or support sustainability initiatives, these machines provide measurable business value.

The question isn’t whether automation makes sense for packaging operations but rather when to implement it and which solution best fits your specific requirements. For many Australian businesses in manufacturing, logistics, FMCG, and e-commerce, that solution is found in a range of automatic carton sealing equipment.