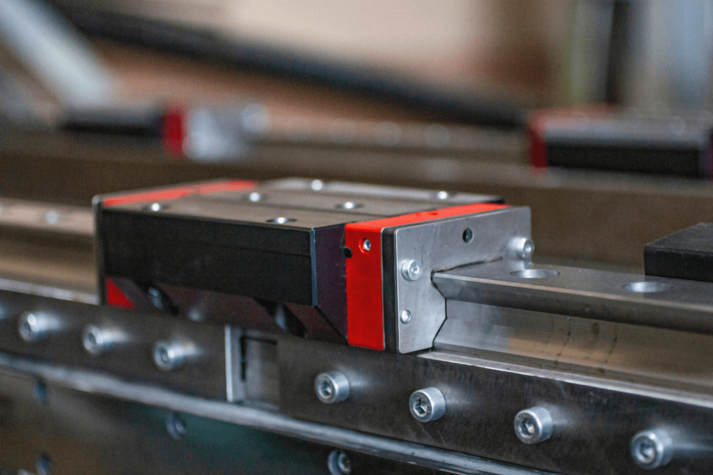

A linear rail is a core component in many types of machinery. From CNC machines and 3D printers to robotics, these precision rails allow for smooth and accurate linear motion. When maintained properly, linear rails can last for years, supporting heavy loads and high-precision applications without loss of performance. Poor care, on the other hand, leads to wear, noise, misalignment, and reduced efficiency.

Why Linear Bearings and Rails Matter

A linear guide rail is designed to provide precise, low-friction movement in one direction. Unlike plain sliding systems, linear rails use balls or rollers within the bearings, making them ideal for high-speed, high-accuracy tasks. They are often paired with a ball screw or rack-and-pinion system to complete a motion assembly.

In industries across Australia, linear rails are used in automation solutions, machining centres, packaging equipment, medical devices, and countless other machines. Because they are relied on for accuracy, downtime caused by rail failure can lead to costly production delays.

Common Issues with Linear Rails

Before looking at maintenance, it helps to know what problems occur when linear rails aren’t cared for:

- Contamination: Dust, chips, and coolant can get into the bearing blocks, causing scoring or seizing.

- Lack of lubrication: Dry rails increase friction, wear down balls, and reduce precision.

- Corrosion: In damp or unprotected environments, rails can rust quickly.

- Misalignment: Improper installation or uneven wear can cause rails to bind.

- Overloading: Rails are designed for specific sizes, loads, and applications. Exceeding these limits shortens service life.

Understanding these risks makes it clear why regular checks and servicing matter.

Basic Tips for Maintaining Linear Rails

1. Keep Rails Clean

The first step in maintaining a linear rail is keeping it free from debris. Chips from machining, dust, or even dried grease can stick to the rail surface and cause damage to both the rail and the linear bearings.

- Wipe down exposed rails with a lint-free cloth.

- Use covers, bellows, or protective boots to shield rails in dirty environments.

- Avoid using abrasive pads that could scratch the precision surface.

2. Lubricate Regularly

Lubrication is essential to reduce friction and extend the life of the rail. A thin, even layer of grease or oil ensures the balls inside the bearings roll smoothly.

- Follow the recommendations from the rail manufacturers or the product manual.

- In light-duty or clean environments, lubrication every few months may be enough.

- In heavy-duty machinery or when handling heavy loads, lubrication should be more frequent.

- Use grease guns with the correct fittings to avoid over-pressurising seals.

3. Inspect for Wear and Damage

Regular inspections help detect issues early. Run your hand gently along the linear guide rail to feel for rough spots, pits, or grooves.

- Check the rail surface for corrosion.

- Look for uneven wear, which may point to misalignment.

- Listen for unusual noises during operation; squeaks or grinding are warning signs.

4. Check for Proper Alignment

Rails must be mounted parallel and straight. Even a small misalignment can cause bearings to bind, leading to excessive wear.

- Use a dial indicator or laser alignment tool during setup.

- For replacement, always check the new rail against the machine’s reference surfaces.

- When cutting or installing rail to fit, make sure ends are square and free of burrs.

5. Match the Rail to the Application

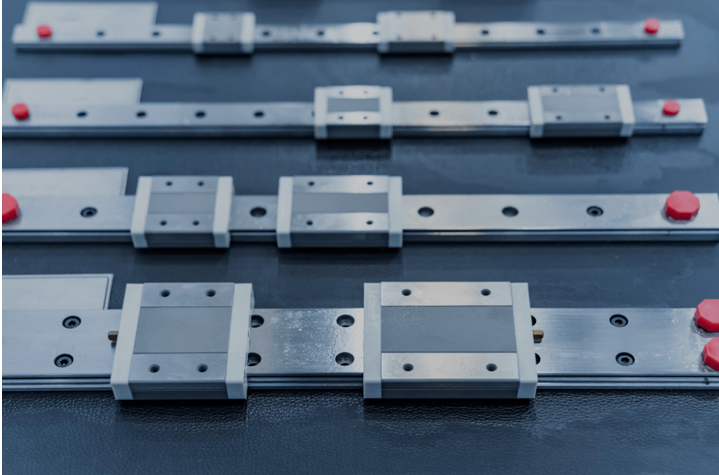

Not all rails are the same. Suppliers offer a wide range of options designed for specific environments and loads.

- For high-speed, high-precision jobs, consider well-known brands like THK.

- For heavy-duty industrial use, choose rails rated for heavy loads.

- For compact equipment, smaller sizes are available without sacrificing performance.

Choosing the right rail reduces stress on components and makes maintenance easier.

6. Replace Worn Components Early

All bearing types, seals, and wipers eventually wear out. Replacing these before failure prevents damage to the more expensive rail itself.

- Keep spare parts in stock for critical machines.

- Monitor bearing play, looseness is a sign it’s time for replacement.

- Always replace with genuine or equivalent-quality parts to maintain accuracy.

7. Protect Against Corrosion

In humid environments or when exposed to coolants, corrosion is a major risk.

- Apply rust-preventive oil if rails are stored for long periods.

- Consider stainless steel or coated rails for demanding conditions.

- Wipe down rails after use in environments where water-based fluids are present.

Advantages of Proper Maintenance

Caring for linear guides and bearings brings clear benefits:

- Extended lifespan: Prevents premature wear and saves on replacement costs.

- Consistent performance: Maintains high precision applications where accuracy matters most.

- Reduced downtime: Avoids unexpected failures that can stop production.

- Lower running costs: Less friction means reduced energy use and less strain on machinery.

For businesses, the advantages are not just mechanical. Well-maintained equipment means more reliable service for customers and smoother day-to-day operations.

Working with Trusted Manufacturers and Suppliers

Not all rails are equal in quality. When selecting rails for your machine, opt for those from trusted manufacturers and local suppliers. Many businesses across Australia stock rails, bearings, and components in different sizes to suit a wide range of equipment.

Check the product page carefully for:

- Load ratings

- Rail material and coating options

- Available cut lengths

- Matching accessories such as bearings, seals, and mounting hardware

By selecting the right products up front, you’ll reduce maintenance needs and ensure compatibility with your application.